Is slow or inaccurate order fulfillment affecting your customer satisfaction and sales on Amazon?

As consumer expectations for fast and precise delivery continue to rise, effective order fulfillment becomes essential for Amazon sellers. This guide looks into the challenges faced by both FBA and FBM sellers in terms of speed and accuracy.

Our Amazon agency will also provide practical solutions to optimize your processes, accelerate shipping times, and minimize errors.

Importance of Speed and Accuracy in Order Fulfillment on Amazon

Speed and accuracy are crucial to successful order fulfillment.

When a customer places an order, they expect their orders to arrive quickly and without errors. Delivering on these expectations is crucial for building customer loyalty and driving sales.

Delays and mistakes can lead to frustrated customers, negative reviews, and increased return rates. Mastering order fulfillment is essential for any Amazon seller looking to thrive in this competitive market.

Both FBA and FBM sellers face unique challenges related to the speed and accuracy of order fulfillment. Understanding these challenges and implementing effective solutions is vital for thriving in the competitive Amazon marketplace.

FBA Fulfillment Challenges: Overcoming Speed and Accuracy Hurdles

While Fulfilled by Amazon offers numerous advantages for sellers, it also presents specific challenges that can impact order fulfillment speed and accuracy. Understanding these obstacles is crucial for optimizing your FBA strategy and ensuring customer satisfaction.

1. Peak Season Delays

During peak seasons like holidays or special sales events, the volume of orders increases significantly. This surge can affect fulfillment operations since it can overwhelm Amazon’s fulfillment centers, leading to slower processing and shipping times.

These delays can result in late deliveries, which frustrates customers and can lead to negative reviews. Prolonged shipping times may also impact sales, as customers may choose competitors for faster delivery.

To mitigate peak season delays, FBA sellers can:

- Increase Inventory Beforehand: Send additional inventory to Amazon well before peak seasons, such as Black Friday, to ensure adequate stock levels.

- Utilize Amazon’s Peak Season Services: Take advantage of Amazon’s tools and services designed to help manage increased order volumes during busy periods.

- Consider Alternative Fulfillment Options: Use a combination of FBA and FBM during peak times to manage higher order volumes effectively.

- Communicate with Customers: Proactively inform customers about potential delays and offer alternative shipping options if possible.

2. Product Damage

Products may be damaged during shipping, handling, or storage within Amazon’s fulfillment centers. Damaged products lead to customer dissatisfaction, increased return rates, and financial losses for sellers.

High rates of product damage can also harm a seller’s reputation and affect their performance metrics.

To minimize product damage:

- Utilize Amazon’s Packaging Guidelines: Adhere strictly to Amazon’s packaging requirements to ensure proper protection for your products.

- Monitor Inventory Health: Regularly check inventory reports for signs of damage and request removal or replacement of damaged items.

- File Damage Claims: Submit claims to Amazon for damaged inventory to seek reimbursement.

3. Picking Errors

Picking errors occur when incorrect items are included in customer orders. This can happen due to mislabeling, poor organization, or human error.

Incorrect items in orders lead to customer complaints, return requests, and negative feedback. It can also cause delays in resolving issues, affecting overall order fulfillment speed and accuracy.

To minimize picking errors:

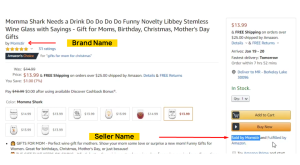

- Clear Product Labeling: Ensure accurate and clear product labels to facilitate correct identification.

- Provide Clear Product Images: Ensure product images accurately represent the item to reduce picking errors.

- Monitor Seller Performance Metrics: Regularly review seller performance metrics to identify areas for improvement, such as order defect rate.

4. Labeling Issues

Incorrect or missing labels can disrupt the order fulfillment process by causing delays in sorting and shipping. Labels are crucial for accurate identification and tracking of products.

Products with incorrect labels may be misrouted or misplaced, affecting fulfillment accuracy.

To prevent labeling issues:

- Adhere to Amazon’s Labeling Guidelines: Follow Amazon’s specific requirements for product labels, including size, placement, and content.

- Use High-Quality Labels: Invest in durable labels with clear and legible print to ensure accurate scanning.

- Double-check Labels: Conduct thorough inspections before sending products to Amazon to verify label accuracy.

- Utilize Amazon’s Label Service: Consider using Amazon’s label service for added convenience and accuracy.

5. Inventory Placement

FBA sellers have limited control over where their inventory is stored within Amazon’s network. However, inventory placement can affect how quickly products can be shipped to customers.

Poor inventory placement can result in longer shipping times if products are stored farther from customers. This can negatively affect delivery speed and increase the likelihood of delays in fulfilling orders.

To potentially influence shipping times:

- Optimize Product Listings: Ensure that product dimensions and weights are accurately listed to help Amazon’s system with better inventory placement decisions.

- Monitor Sales Performance: Track product sales to understand trends and adjust inventory management strategies accordingly.

- Consider Fulfillment by Amazon Inventory Placement Service (IPS): Explore Amazon’s IPS if available to potentially influence inventory distribution.

6. Carrier Performance Issues

Carrier performance, including shipping delays, lost packages, and damaged shipments, can impact the overall fulfillment process.

Problems with carriers can lead to delayed deliveries, customer complaints, and a damaged seller reputation. Inconsistent carrier performance can also disrupt the reliability of the fulfillment process.

While FBA sellers have limited direct control over carrier performance, understanding the potential challenges and implementing effective strategies can help mitigate their impact:

- Monitor Carrier Performance: Track carrier delivery performance metrics to identify potential issues.

- Communicate with Customers: Proactively inform customers about the delivery times and potential shipping delays due to carrier issues.

- Leverage Amazon’s Carrier Network: Utilize Amazon’s preferred carriers when possible to benefit from their network and resources.

- File Claims: File claims with Amazon for lost or damaged packages to seek reimbursement.

FBM Fulfillment Challenges: Overcoming Speed and Accuracy Hurdles

Fulfilled by Merchant offers sellers greater control over their fulfillment process, but it also comes with unique challenges that can impact order fulfillment speed and accuracy.

By understanding these obstacles and implementing effective strategies, FBM sellers can optimize their operations and deliver exceptional customer experiences.

1. High Order Volume

High order volume directly impacts order fulfillment speed and accuracy.

As order volume increases, the potential for processing delays, picking errors, and shipping inaccuracies rises. Overwhelmed staff may rush through orders, leading to mistakes.

To mitigate these issues:

- Prioritize Efficient Order Handling: Establish streamlined workflows and allocate resources effectively to manage increased order volume.

- Implement Quality Control Measures: Conduct regular audits and training to minimize errors and ensure order accuracy.

- Leverage Technology: Utilize order management, warehouse management, and shipping software to create automation in your processes and improve efficiency.

Here is a a handy spreadsheet of Amazon’s sorting and fulfillment centers

2. Manual Order Picking

Manual order picking can be time-consuming and prone to errors, especially during peak periods or when dealing with a large product catalog. This can result in increased picking time, picking errors, and inefficient use of labor.

Here are ways to optimize order picking:

- Implement Pick-to-Light Systems (PTL): Using PTL systems guides pickers to the correct items and quantities, reducing errors, and increasing efficiency.

- Optimize Warehouse Layout: Design the warehouse for efficient order picking, minimizing travel distances, and maximizing pick density.

- Train Pickers Thoroughly: Provide comprehensive training on picking procedures, product knowledge, and order accuracy.

- Conduct regular performance reviews: Monitor picker performance and provide feedback for improvement.

3. Packaging and Order Accuracy

Accurate and efficient packaging is essential for FBM sellers to maintain order accuracy and prevent shipping errors. Incorrect or inadequate packaging can lead to product damage, incorrect item fulfillment, and increased return rates.

This is how to solve this problem:

- Standardize Packaging Materials and Sizes: Create consistent packaging guidelines to reduce errors.

- Invest in Quality Packaging Supplies: Use durable materials to protect products during transit.

- Train Staff on Proper Packaging Techniques: Ensure employees understand packaging procedures and best practices.

- Utilize Packaging Software or Templates: Streamline the packaging process and reduce errors.

- Conduct Regular Packaging Audits: Inspect packaging materials and processes to identify areas for improvement.

4. Shipping Delays

Shipping delays can significantly impact customer satisfaction and an FBM seller’s reputation. Factors such as carrier performance, traffic congestion, and weather conditions can contribute to these delays.

To solve this issue:

- Carrier Selection: Choose reliable delivery service providers with a proven track record.

- Shipping Software: Utilize shipping software, like ShipStation, to optimize routes and track real-time shipments.

- Proactive Communication: Inform customers about potential delays if you expect to not meet the delivery promised date.

- Backup Shipping Options: Outsource alternative shipping methods for urgent orders to ensure fast and reliable shipping.

- Customs Clearance: Ensure accurate documentation for international shipments.

Want to learn more about shipping your Amazon products as an FBM seller? Check this video guide.

Key Points:

- Seller Control: FBM sellers have full responsibility for shipping, which can lead to delays if not managed effectively.

- Carrier Impact: Shipping carriers significantly influence delivery times, and sellers must choose reliable options.

- Free Economy Shipping: Amazon’s default free economy shipping can cause delays and impact customer satisfaction.

- Accurate Shipping Estimates: Setting realistic shipping times is crucial for managing customer expectations and avoiding negative feedback.

- Additional Considerations: Factors like shipping options, carrier performance, and customer communication influence overall shipping success.

5. Customer Service Issues

FBM sellers face significant customer service challenges that impact the speed and accuracy of their order fulfillment. They often handle a high volume of customer inquiries, which can overwhelm their resources and slow down response times.

Managing customer expectations is crucial, as misalignments can lead to dissatisfaction. The complexities of processing returns and refunds add to the burden, making efficient handling a persistent issue.

Additionally, resolving order-related problems swiftly is essential to prevent negative feedback, which can harm the seller’s reputation.

To mitigate these issues:

- Dedicated Customer Support Team: Allocate resources for handling customer inquiries efficiently.

- Customer Relationship Management (CRM) Software: Utilize CRM to track customer interactions and preferences.

- Clear Communication Channels: Provide multiple channels for customers to contact support.

- Efficient Return Process: Establish a streamlined return policy and process.

- Proactive Issue Resolution: Address customer concerns promptly and effectively.

6. Lack of Visibility and Control

FBM sellers have limited visibility into the entire fulfillment process compared to FBA. This lack of control can lead to challenges in tracking orders, identifying issues, and making timely adjustments.

Here are the ways to solve this issue:

- Utilize Order Management Software: Implement a robust order management system to track orders, manage inventory, and communicate with customers.

- Integrate with Carrier Tracking Systems: Connect with carrier systems to provide real-time shipment updates and identify potential delays.

- Implement Inventory Management Systems: Gain better visibility into stock levels and prevent stockouts or overstocks.

- Proactive Communication with Customers: Keep customers informed about order status and shipping updates.

- Conduct Regular Performance Reviews: Evaluate fulfillment processes and identify areas for improvement.

Here is an article on how to successfully sell on Amazon without using FBA

Optimize Your Amazon Fulfillment Strategy

Mastering order fulfillment is essential for the success of any Amazon seller. By understanding the unique challenges of FBA and FBM, and implementing effective strategies, businesses can optimize their operations, enhance customer satisfaction, and drive sales.

Whether you’re an FBA or FBM seller, prioritizing speed, accuracy, and efficiency is crucial. By effectively managing inventory, order processing, shipping, and customer service, you can create a seamless fulfillment process that sets your business apart.

By following the insights and strategies outlined in this guide, you can overcome fulfillment hurdles and build a thriving Amazon business.

Need help with optimizing your Amazon business? Contact our Amazon agency today!