Selling on Amazon comes with the challenge of managing inventory and fulfillment efficiently. When unexpected Amazon shipping restrictions occur, it can lead to lost sales and frustrated customers if you’re unprepared.

Managing an Amazon shipping strategy effectively involves keeping track of inventory levels, monitoring fulfillment timelines, and adjusting quickly when delays happen. Staying on top of these tasks helps prevent stockouts and ensures customers receive their orders on time.

In this article, we cover the most common Amazon shipping and inventory challenges sellers face and provide practical strategies to manage them effectively. Our Amazon agency will also share actionable tips for maintaining sales, adjusting fulfillment, and keeping operations running smoothly despite unexpected restrictions.

Stay Ahead of Shipping Challenges

Learn how to manage Amazon shipping restrictions and avoid stockouts before they impact your sales.

Shipping and Inventory Challenges on Amazon

Even experienced sellers can be caught off guard by shipping and inventory challenges. Recognizing these issues in advance helps you stay prepared and reduce disruption.

1. Unexpected Shipping Restrictions

Amazon may limit the quantity or type of products you can send to FBA without warning. These restrictions can delay replenishment, making it harder to maintain stock for fast-moving items.

2. Stockouts

Running out of inventory is a constant risk, particularly for high-demand products. Stockouts can reduce sales, hurt your ranking, and impact your Buy Box eligibility.

3. Inventory Mismanagement

Tracking multiple SKUs and fulfillment channels can quickly become complex. Without careful oversight, you may overstock some items while understocking others, affecting cash flow and sales performance.

4. Long-Term Storage Fees

Slow-moving inventory in Amazon warehouses can lead to significant storage fees. Managing inventory turnover efficiently is critical to protecting your profits.

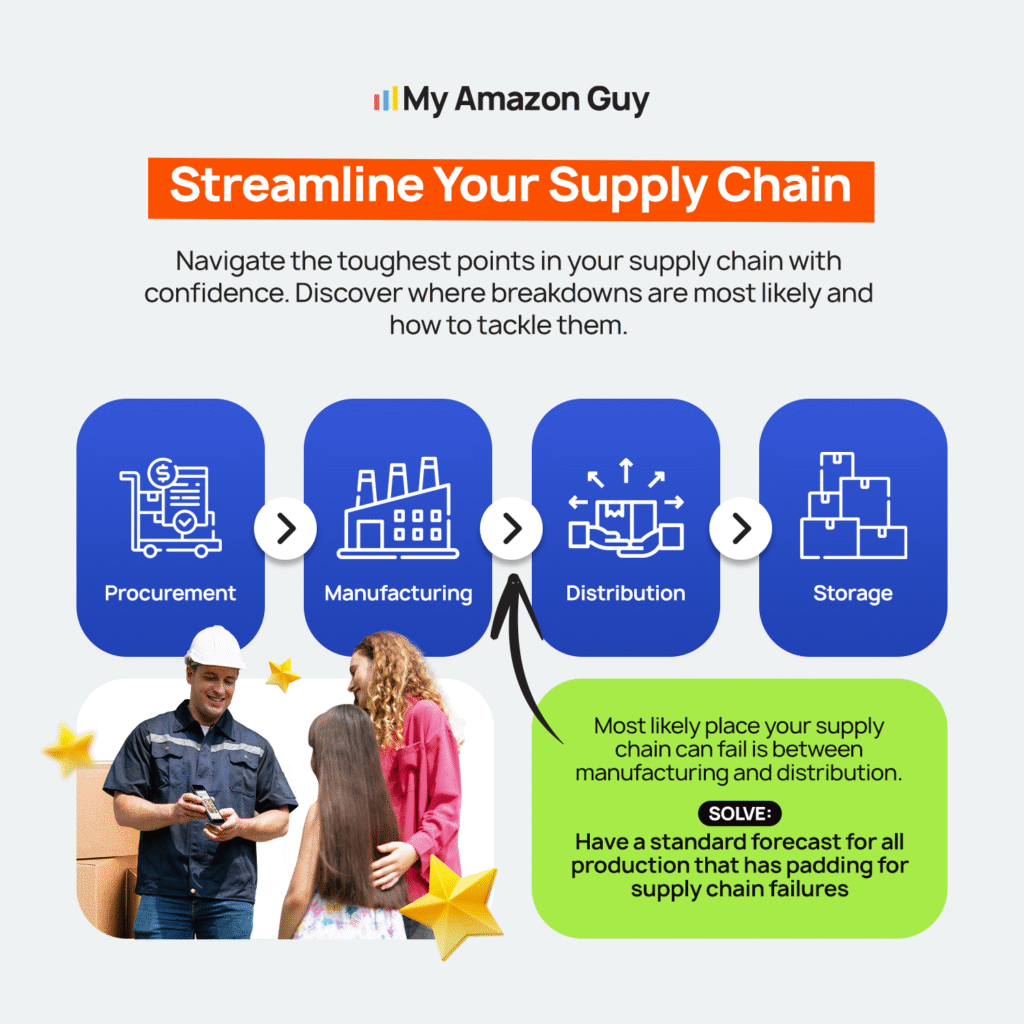

5. Supply Chain Delays

Even when shipping is allowed, suppliers or carriers may experience delays. These disruptions can make it difficult to replenish stock on time, leading to missed sales opportunities.

How to Handle Unexpected Shipping and Inventory Issues

Shipping restrictions and inventory delays don’t have to derail your business. The following strategies help you maintain operations even when Amazon’s FBA system imposes limits.

1. Monitor Your Ad Campaign Budgets Closely

When inventory is tight, campaigns may spend faster than expected. Increasing the budget on profitable campaigns ensures you continue capturing sales while inventory lasts.

2. Switch Key SKUs to Merchant Fulfilled When Needed

If FBA becomes restricted, consider shifting products to Merchant Fulfilled. Creating MFN versions of your SKUs gives you flexibility when FBA timelines are unpredictable.

3. Accept Limits You Can’t Bypass

Sometimes shipping restrictions can’t be lifted through tickets or calls. Focus on adjusting your fulfillment plan instead of trying to fight Amazon’s system.

4. Adjust Pricing to Protect Inventory

Small price changes can slow sales just enough to stretch remaining stock. This prevents stockouts while maintaining margins.

5. Maintain MFN Operations While Sending Inventory to FBA

Even if FBA is delayed, continue preparing and sending shipments in the background. Rely on MFN listings to keep your Buy Box share steady while FBA catches up.

Stay Ahead of Amazon Shipping Challenges

Many sellers face unexpected shipping and inventory challenges that disrupt sales and impact customer satisfaction. Fortunately, there are proven practices that Amazon sellers can implement to minimize delays and keep operations running smoothly.

Need help managing Amazon shipping restrictions and inventory issues? Contact our full-service Amazon agency and let our team handle the complexities so you can focus on growing your business.

Protect Your Inventory

Implement proven strategies to keep your inventory balanced and your Buy Box share steady.